Bread Packing Machine

Bread Packaging Machine | Bread Wrapping Machine

Model: TH-450

Film width: Max. 450mm

Bag length: 130-450mm

Bag making width: 50-180mm

Packing speed: 30-180bag/min

Machine size: (L)4020×(W)820×(H)1450

Weight: 900Kg

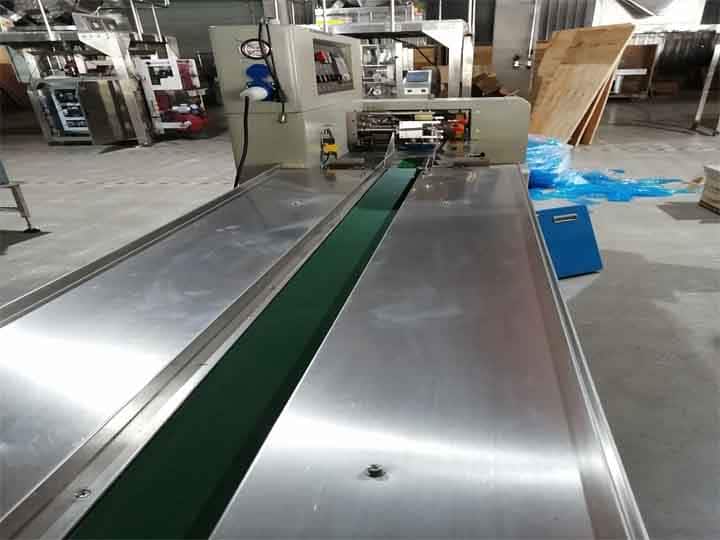

The bread packing machine is a kind of horizontal flow wrapping machine, so it is also called a bread wrapping machine. It can automatically finish the process of feeding, bag making, sealing, and cutting. Our automatic bread packing machine can greatly enhance your efficiency and benefit your project.

It is suitable for packaging various food and non-food products, such as bread, bakery, biscuits, vegetables, fruits, face masks, chocolate, and many other products. Taizy Packaging Machinery LTD is a professional bread packaging machine manufacturer with rich experience. Welcome to get in touch with us for the best price.

What is a bread packing machine?

Taizy bread packing machine is a type of pillow packing machine. The bread is soft, so ordinary packing machines can not package bread individually. Due to its unique and reasonable structure, the Pillow packing machine can finish the completely automatic packaging of bread. And do not damage its shape. With an intelligent PLC control system and advanced technology, a pillow flow wrapping machine is very easy to operate. This can greatly save your labor costs.

Applications of the bread packing machine

This machine is widely used for food packaging, such as bread, chocolate, biscuits, vegetables, fruit, etc. Moreover, it is also suitable for other products like metal fittings, daily necessities, plastics, and other fields.

Structures of the bread packaging machine

The horizontal packaging machine comprises an English control area, linkage roll film shaft, temperature real-time controllable, sealing area, and date printer. Each part controls different functions. A brief introduction to the bread packaging machine is as follows.

- English Language Available

Our bread packing machine adopts a large touch screen, the input method adopts Chinese and English switching mode - Linkage Roll Film Shaft

The linked roll film shaft works better than a single roll film shaft. Because there are many kinds of materials for the film - Temperature Real-time Controllable

When the pillow packaging machine starts to pack, according to the characteristics of the film material, we recommend adjusting the temperature to about 125 degrees Celsius to ensure a good sealing effect - Sealing Area

The roll film is pre-packaged through the heat-sealed area. The two rollers are called the film-sealing wheel. - Date Printer

The printer device can print the date, production serial number, QR code, etc.

Working principle of the bread wrapping machine

- The bread packing machine is a continuous packaging machine with a strong packaging capacity, suitable for various specifications of food and non-food products.

- The pillow packaging machine adopts cutting and walking methods, and the high-sensitivity photoelectric eye tracking will not close empty bags or cut diagonally.

- The horizontal packaging machine adopts dual frequency converter control, which saves time and film at one time

- The man-machine control interface and automatic diagnosis function are adopted in the operation, and equipment failure is easy to detect.

The power system of the bread packing machine

The power used by the bread packaging machine is a motor. Most packaging machines generally use variable frequency motors and servo motors can also be used. One machine has two motors. The large motor controls the conveyor belt at the inlet, the conveyor at the outlet, and the cutter. A small motor controls the film roll.

Servo motors can be used when cutting the packaging of products with irregular lengths. The servo motor can automatically sense the cutting length of the object to avoid cutting errors. For example, when packaging noodles, vegetables, fruits, and other products, the servo motor is the best choice because the packaging length of these products is not fixed.

Main advantages and structural characteristics

- Double inverter control, the bag length is set and cut immediately, there is no need to adjust the empty run, one step in place, saving time and film.

- Human-machine interface, convenient and quick parameter setting.

- Fault self-diagnosis function, clear fault display.

- High-sensitivity photoelectric eye color mark tracking, digitally input sealing and cutting position, making sealing and cutting position more accurate.

- Temperature-independent PID control is better suitable for various packaging materials.

- Positioning stop function, no sticking knife, no waste film.

- Simple transmission system, more reliable work, and more convenient maintenance.

- All controls are realized by software, which is convenient for function adjustment and technology upgrade, and never lags.

Bread packing machine price

Are you curious about the cost of a bread packing machine? The price of a bread packing machine can vary based on factors like features, capacity, and brand. To find the best deal, consider your specific packaging needs and compare options from reputable suppliers.

Whether you’re running a small bakery or a large-scale production, investing in efficient bread packaging equipment is crucial for optimizing your workflow. Explore our comprehensive guide to discover the factors influencing the price of bread packaging equipment and make an informed decision for your business.

Two types of TZ-450 bread packaging machines

The roll film of the bread packaging machine has two conveying modes, namely upper feeding and lower feeding. The roll film is on the top of the machine for the top feeder, the former can be fine-tuned, and the vertical cutter is inside the machine.

Down-feeding paper packaging machine, the film roll is under the machine, and the former is not adjustable. You can purchase different formers to change the cutting width. In the process of using the motor, you can adjust the cutting width of the machine according to your needs. The maximum cutting circumference of the TZ-450 is 450mm.

Parameters of the bread packing machine

| Model | TH-450 |

| Film width | Max. 450mm |

| Bag length | 130-450mm |

| Bag making width | 50-180mm |

| Product height | Max.70mm |

| Film roll diameter | Max. 320mm |

| Packing speed | 30-180bag/min |

| Power Specifications | 220V,50/60HZ,2.6KVA |

| Machine size | (L)4020×(W)820×(H)1450 |

| Machine quality | 900Kg |

| Remarks | be able to customize |

Model TH-450 bread packing machine can pack 30-180 packages of products per minute. The size of the machine is 4020x820x1450mm. do you have some special needs, we can provide a unique customization service for you. Welcome to contact us for the latest quotation.

In our company, we also have other packaging machines for sale, such as vacuum packaging machines, powder packaging machines, and so on.

Toolbox display

This horizontal packaging machine is equipped with a toolbox. The toolbox includes wrenches, screwdrivers, 9 sizes of Allen wrenches, cutters, motor belts, and two heating wires. You can install and operate the machine according to the instructions. The bread packaging machine is easy to install and operate. Our Taizy Machinery company technical staff will provide you with guidance at any time.